What we do

A development process has been started to result into the creation of an entire production line. Scientific R&D, combined with hands on practice of farmers and entrepreneurs, proved to be an excellent base for in depth theoretical discussions and practical executable solutions. Keeping the work in our own hands, developing the hardware and building of the production site ourselves speeding up the development.

Setting up the test unit and finally the entire production scale pilot installation results in the development of specific components and techniques by the BioLake team:

- Biolake is developing a torrefaction process specifically usable for "dry agricultural residues", like straw, cane, woodchips and miscanthus.

- Fundamental studies at the Eindhoven Technical University, TU/e, have shown that, for the use of straw and hay as a feed-stock, a screw-in-through type system is best suited to reduce flow problems and avoid thermal control irregularities. Biolake developed a new screw system.

- All components in the production system designed, comprising dryers, reactor, and cooling units are based on simple steel as construction material whereas specific design precautions are adopted to optimise drying rate, mixing and heat transfer.

- The heater is being developed by the Biolake team as well. With the heater it is possible to use the gases from the torrefaction process itself, the use of natural gas is avoided during the process.

- Keeping oxygen out of the process is another major challenge. To enable a continues process a lock on the entrance and output side of the process is a must. The BioLake team is developing these locks based on an Agricultural technology.

- The last step is tuning the system for the several organic residues.

After the first test procedures, Biolake patented the system in December 2010. The patent request (PCT route) exists of five claims. BioLake also developed a lot of IP along the process and intents to keep doing so in future.

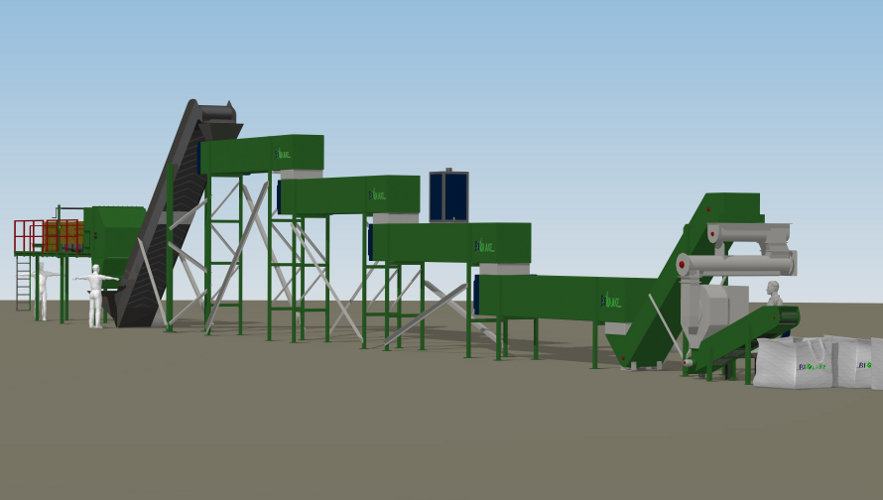

A real life 1-1 unit

Currently a standard torrefaction production unit is being engineered, designed and built. Length of this demonstration and production unit is 24 meters and has a width of 1.5 meters, excluding the chopper and conveyor at front and the pelletizer at the back. These are of course part of the demonstration unit.